Traction Motors and Traction Converters

The design and manufacture of Škoda Electric traction motors is based on a set of key requirements: High reliability and safety, high economy, low energy consumption, robustness, low life cycle costs and maximum environmental friendliness.

Traction motors

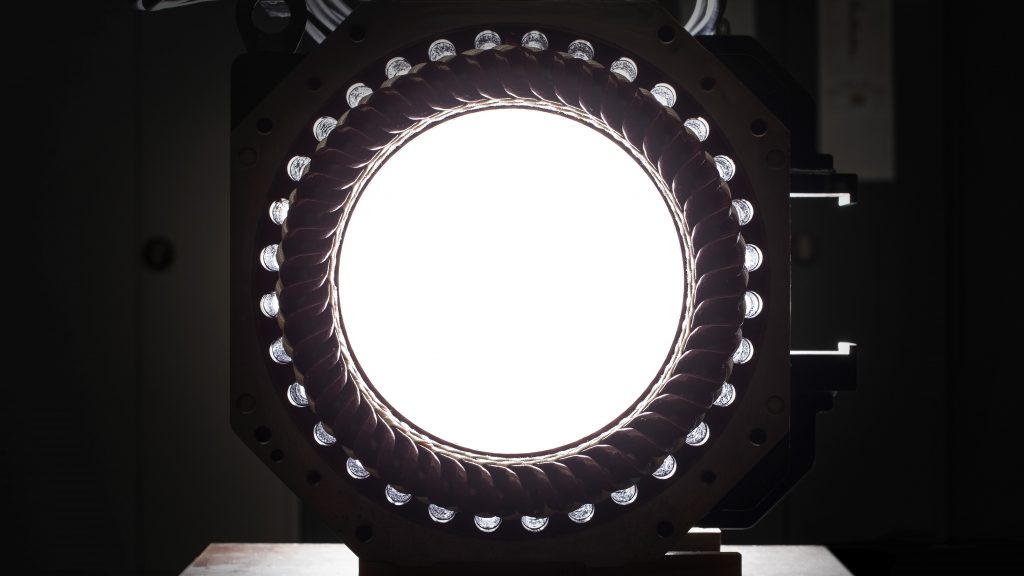

Almost 50,000 traction motors have been sold to customers around the world. The compact design of traction motors is optimized for performance, robustness and mechanical, electrical and thermal properties through modern analysis and synthesis. The results of simulations and prototypes of traction motors are verified both in our own test center and during the verification of the driving characteristics of vehicles on the test circuit and during operation. Quality and durability are ensured by comprehensive testing of all components during production. In addition to testing the traction motors themselves, our test center also tests and checks the compatibility of the entire traction chain, including traction transformers, traction converters and gearboxes. Škoda provides solutions tailored to the design requirements of each vehicle. Škoda’s portfolio includes asynchronous and synchronous (iPMSM) traction motors of all power categories.

Traction converters

For many years, Škoda Electric innovations have set high standards in traction converters. As a pioneer, Škoda Electric introduced the first IGBT traction converter in 1995 and the first SiC MOSFET converter in 2015. The modular design allows considerable flexibility in adapting systems to individual customer requirements. In addition, the modules are easily accessible for maintenance and repairs. The lower weight contributes to the lightweight construction of rolling stock. In the introduction and continuous development of three-phase AC technology for traction applications, we use the latest technologies to further increase the competitiveness of our customers, not only through innovations in the field of energy components, but also in the field of power converter control.

Auxiliary drives

Due to the growing demands for modern mobility, the importance of power supplies for electrical and electronic appliances for on-board applications such as air conditioning, lighting, cooling and ventilation is also growing, as are WiFi connections, sockets for charging laptops and mobile phones. Škoda Electric auxiliary converters are robust, reliable, powerful and innovative, and thanks to these features they are an important connection between individual devices and appliances on board vehicles. Compactness and modularity are the focus of our design to achieve the optimal system concept with optimal performance with reliable components and certification for use worldwide. The portfolio of Škoda auxiliary converters includes all standard voltages that allow us to implement tailor-made solutions for our customers at a reasonable price.