Modernisation of Air Conditioning and Heating of RegioJet Vehicles

The aim of the project is to replace a substantial part of the electrical equipment of passenger cars with a high failure rate and considerable maintenance requirements due to wear.

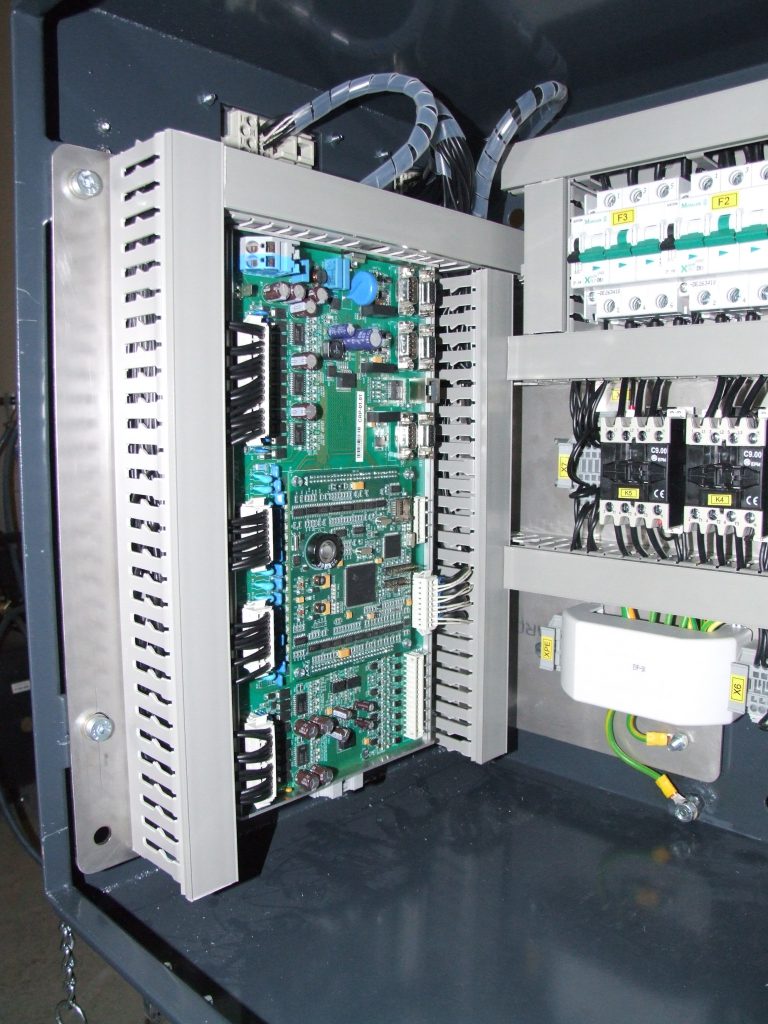

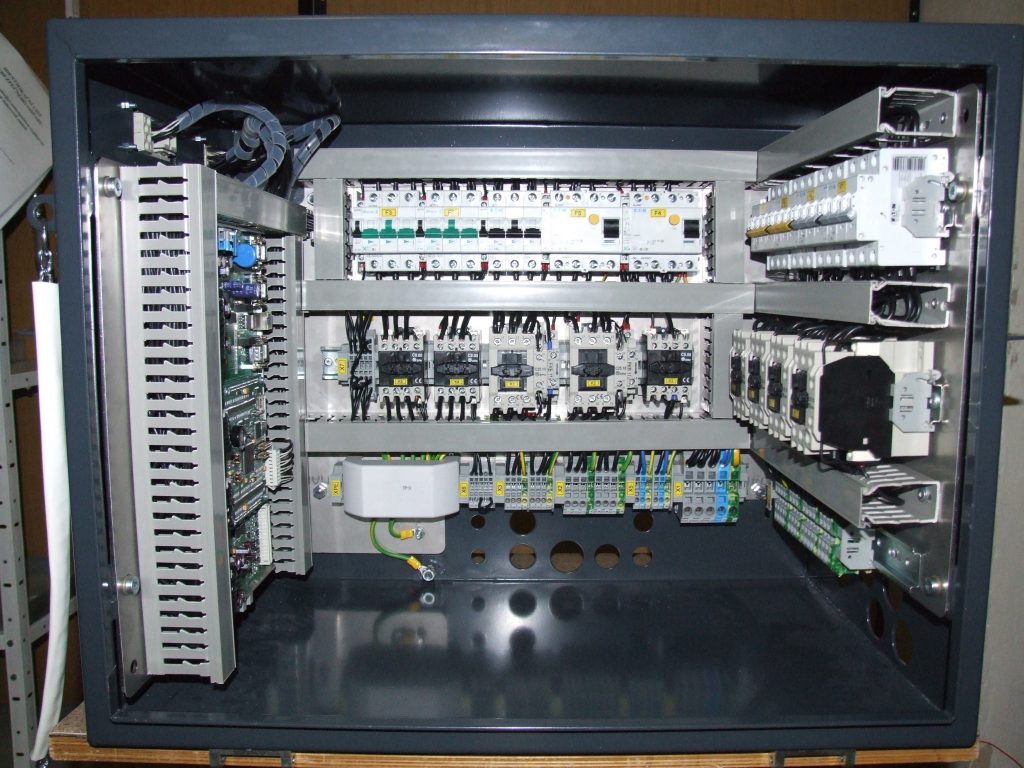

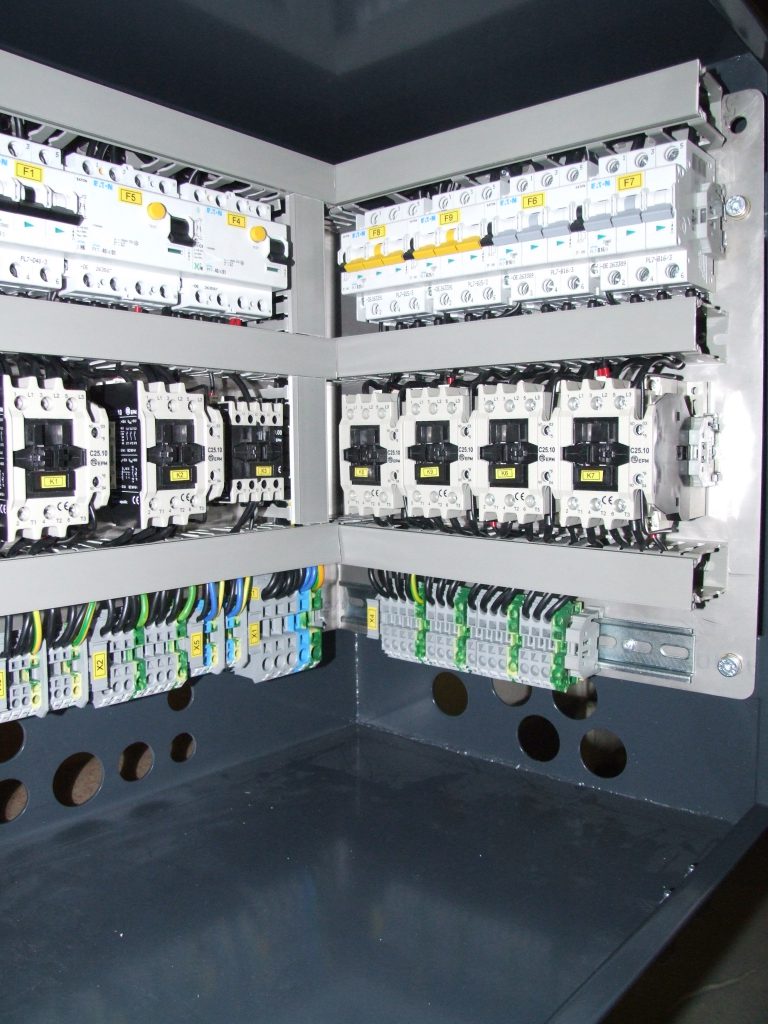

After analysing the problems and based on experience with vehicle operation, the customer sought solutions to replace an obsolete air conditioning unit powered by a high voltage motor with a high frequency of failures by replacing air conditioning and heater control circuits, as well as by replacing the sizeable original high voltage converter called CZE (central energy source). Through an analysis of customer requirements and a detailed examination of the condition and design of the original electrical equipment, it was decided to completely replace the air conditioning unit, air conditioning and heater control circuits, and the high voltage converter (CZE). The original heating, evaporator and air supply fan container will remain in the vehicle, but it will be modernised and new analog temperature sensors based on NTC sensors will be added. The customer also wanted to consider removing unreliable and obsolete detection components of the connected traction power supply system and configuration HV power circuits. On the basis of these requirements, we decided to integrate a compact CZE converter designed for installation under the vehicle, which allows operation on all standard power supply systems of the traction system. In order to terminate HV detection and configuration circuits, original HV heating registers had to be connected to a new three-phase power network (3x400V/50Hz), which is powered by the new integrated converter. Our company developed its own new controller unit with two boards (interface board and processing unit) based on an analysis, labour requirements and the low required prices for renovation. Both units (boards) are connected to each other with comb connectors. The control board assembly is placed and mounted in an aluminum profile enclosure, which can be installed on a standard DIN rail. The entire control unit, including the enclosure, is installed on the side wall of the air-conditioning unit’s junction box. The location of the new control part (circuits), including new power contact switching elements, was designed and engineered as a control cabinet – inserted in the side of the new air conditioning unit – accessible from the side of the vehicle for easy access by maintenance technicians. In addition to the contact elements (contactors), which control the power supply to the air conditioning compressor, and a total of four stages of electric heating, this box also contains all the necessary fuse elements (circuit breakers and residual-current devices) that protect the heating and air conditioning compressor circuits. The project also required a solution for the method of electrical connection of the new part (particularly control circuits) to other unchanged electrical equipment. This particularly includes the connection of logic or analog signals such as: vehicle power supply, battery undervoltage protection, monitoring of the air flow and correct operation of the supply fan, connection of heating pipe/evaporator protection thermostats, action elements such as supply air fan motor power supply contactors, control of the solenoid valve cooling the air conditioning circuit, control of the original status indicators in the vehicle’s switchboard, boarding area heating control, control of the original recirculation valves, etc. Solving the issue of measuring and regulating temperatures in individual compartments of the vehicle was also an integral part of the project. Each compartment contains a solenoid valve that can be controlled in two states in open – closed mode. After the original parts of the compartment were analysed – which were to be preserved for financial reasons (air ducts with solenoid valves) – the original units were developed and equipped with switches for correcting the required temperature, measuring the room temperature and controlling the solenoid valve – a new processing unit and application software were developed, which enabled easy installation and provision of the necessary local functionality. The compartmental units were designed with a duplex RS485 communication line. The RS485 line is installed throughout the vehicle and all individual modules. Each module connected to the communication line has a unique address. This unifies the module in terms of hardware and software. The RS485 line is also introduced into the central control unit, which receives accurate information about the temperature in individual compartments thanks to compartment modules, as well as information about the temperature preset by passengers, and it can turn individual control valves in each compartment on or off based on the current temperature and the required temperature, allowing it to achieve the optimal temperature according to passenger requirements.

Characteristics

- Compatible with TST (Tunning and Service Tool)

- Advanced diagnostic possibilities, event and operational data log

- New temperature regulation in each train compartment

- High reliability of electric components

- Refurbishment of certain original components

- New control circuits

- Preparation of complete documentation for the air conditioning system

ABOUT THE PROJECT:

- Customer: RegioJet, a.s.

- Year of implementation: 2013-2016

- Number of vehicles: 40

- Place of operation: Czech Republic

Technical parameters

- Rated cooling capacity 50 kW

- Rated heat output 33,5 kW

- Rated power supply voltage 3 x 400 V, 50Hz

- Rated control voltage 24V DC

- Refrigerant in the compressor circuit R134a

- Weight 680 kg

- Maximum air supply 11,800 m3/h.

- Operating temperature range -40 °C to + 45 °C