Air Conditioning and Heating System for the Škoda 28T Konya Tram

The air conditioning and heating system for the Škoda 28T tram is designed for cooling, ventilation, heating and conditioning of the air supplied to the passenger compartment and the driver's cabin in the tram.

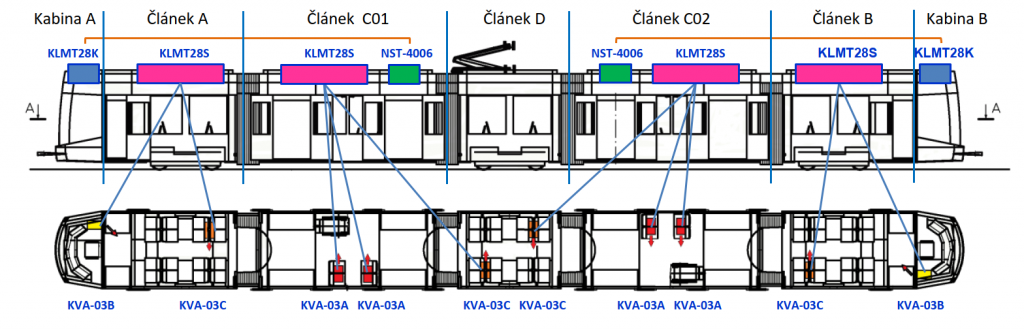

Four main systems were implemented in the project:

- KLMT28S passenger compartment air conditioning units

- KLMT28K air conditioning units for the driver’s cabin

- NST-4006 power converters for the KLMT28K unit

- three types of KVA-03 heating units

In each air conditioning unit, fresh air is supplied via a controllable valve to the mixing chamber, where it is mixed with recirculation air. From the mixing chamber, air is supplied via a filter, cooler (evaporator) and electric heater to the vehicle’s air pipes. Filters prevent the entry of dirt and dust into the entire air conditioning unit, as well as the clogging of coolers, heaters and fan impellers. The cooler (evaporator) of the air conditioning units reduces the air temperature. It is part of the cooling circuit together with the compressor and is filled with R134a refrigerant. The cooling capacity is controlled by changing the speed of the compressors with a frequency converter. Heating power is controlled by controllers that allow continuous change of the voltage of the electric heaters with semiconductor converters. The advantage of this is that it makes it possible to achieve a better curve of the controlled temperature (higher comfort for passengers) with a significantly smaller frequency of heating system contactor switching. In the passenger compartment, heating with KVA-03 heating units is preferred. It also prevents cold air from flowing from the air conditioning units in heating mode to passengers. To reduce the relative humidity, the air conditioning unit is equipped with a dehumidification mode. This mode allows starting the compressor cooling circuit together with the electric heater. The air conditioning and heating system is automatic and it operates according to the required parameters set by the driver. Each air conditioning unit contains a control unit. Communication with the host control system of the vehicle takes place via a secured Ethernet line. The air conditioning units are designed to be mounted on the vehicle’s roof. The top lids of the units are fully passable. The aluminum structure of the container and the integrated power converters help achieve a low specific weight. The air conditioning unit in the passenger compartment is equipped with an integrated compact power converter with galvanic isolation and inverters. This allows them to be powered directly from the 600 V or 750 V DC traction network.

Characteristics

- Control via automotive Ethernet

- Compatible with TST (Tunning and Service Tool)

- Integrated frequency converters

- Continuous control of fans and compressor speed

- Contactless heating system control

- Power supply from overhead line

- Advanced diagnostic possibilities, event and operational data log

Technical parameters of the KLMT28S unit

- Rated cooling capacity of the unit 20 kW

- Rated heat output 8 kW

- Rated power supply voltage 750 V DC

- Operating range of supply voltage 500 V – 1000 V DC

- Rated control voltage 24V DC

- Refrigerant in the compressor circuit R134a

- Weight of cooling circuit components 399 kg

- Maximum air supply 3,000 m3/h.

- Operating temperature range -40 °C to + 45 °C

- Communication interface Ethernet

Technical parameters of the KLMT28K unit

- Rated cooling capacity of the unit 4 kW

- Rated heat output 5 kW

- Rated power supply voltage 3 x 400 V, 50Hz

- Rated control voltage 24V DC

- Refrigerant in the compressor circuit R134a

- Weight of cooling circuit components 150 kg

- Maximum air supply 3,000 m3/h.

- Operating temperature range -40 °C to + 45 °C

- Communication interface Ethernet, CAN

Technical parameters of the NST-4006 power converter

- Rated heat output 6 kW

- Rated power supply voltage 750 V DC

- Operating range of supply voltage 500 V – 1000 V DC

- Output voltage 3 x 0 až 400 V, 0 – 50 Hz

- Rated control voltage 24V DC

- Weight of cooling circuit components 55 kg

- Cooling Natural

- Communication interface CAN

ABOUT THE PROJECT:

- Customer: ŠKODA TRANSPORTATION a.s.

- Year of implementation 2013-2015

- Number of vehicles: 72

- Place of operation: Konya, Turkey