Air Conditioning and Heating System for Škoda 39T Ostrava and 40T Plzeň Trams

The air conditioning and heating system for Škoda 39T and 40T trams (FCx concept) is designed for cooling, ventilation, heating and conditioning of the air supplied to the passenger compartment, and for the driver's cabin in the tram.

This is the third generation of POLL air conditioning units. The units have been completely redesigned in order to reduce their weight and increase their capacity. The cooling of power converters is a new concept, where the heat loss does not reduce the cooling capacity of the air conditioning system, but is dissipated to the environment through condenser fans.

The system consists of three main devices:

- KLM-T2520.PLZ01 passenger compartment air conditioning units

- KLM-T0507.PLZ01 air conditioning units for the driver’s cabin

- next generation KVA-03 heating units

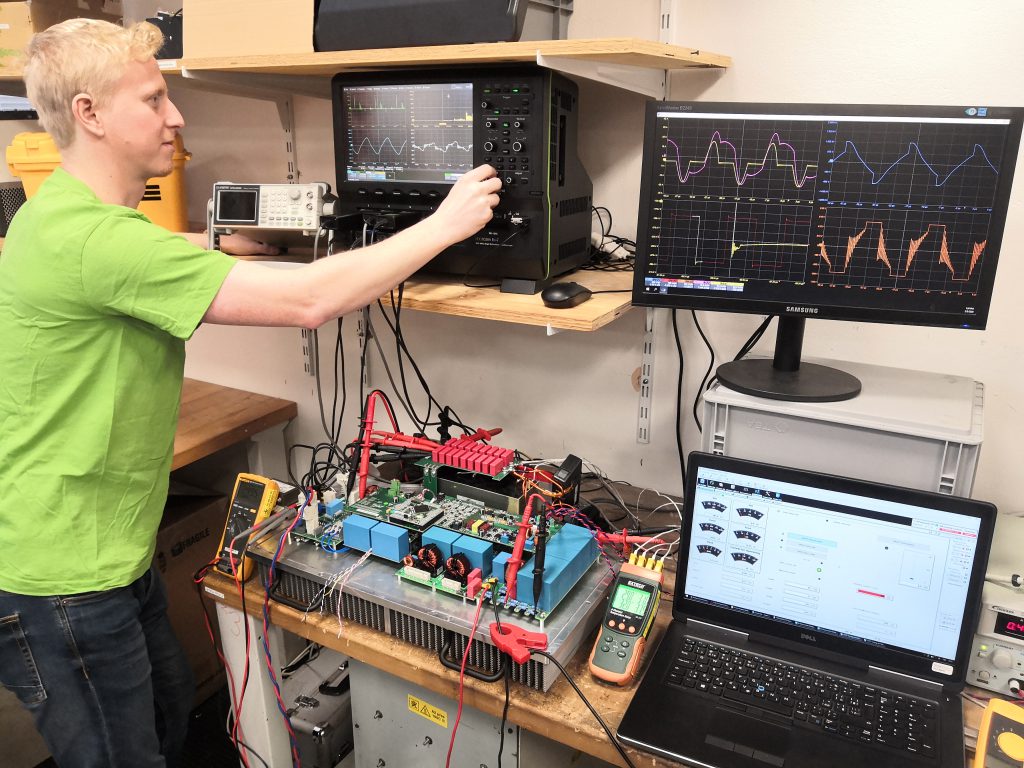

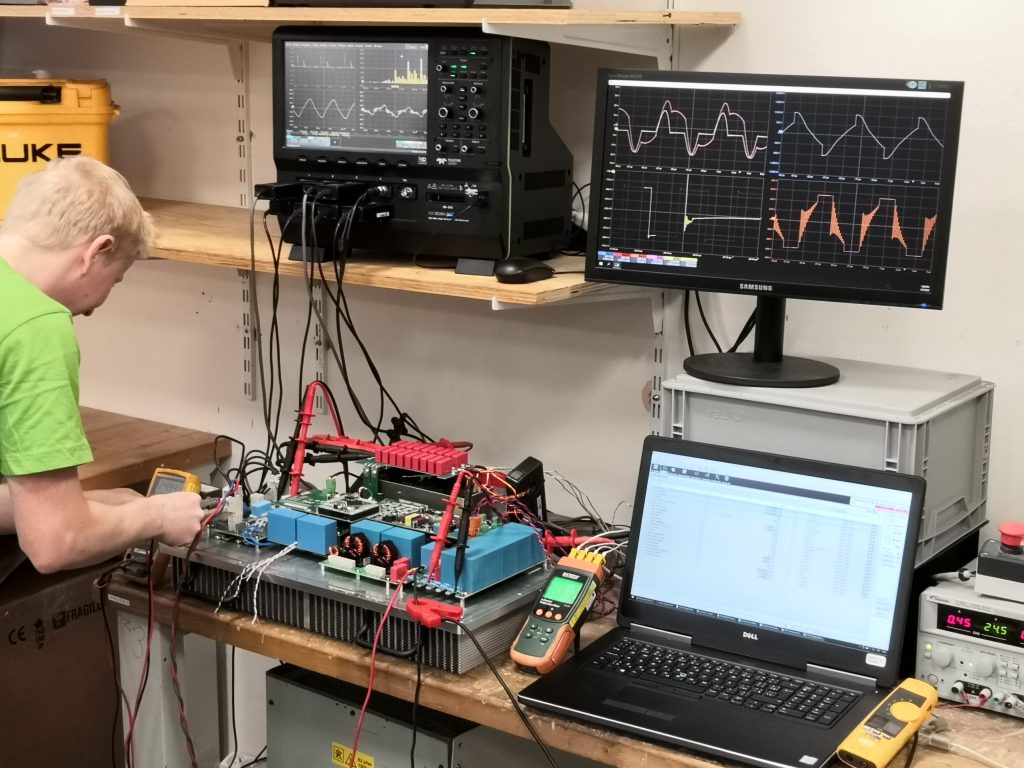

The interior heating units contain a contactless switch and their own control unit with a CAN line, which has improved control of thermal comfort in the vehicle. Temperature sensors are now also used on the side of the air intake into the units. This allows us to know the temperature distribution in the whole vehicle, which is an important parameter for improving thermal comfort control. The passenger compartment and driver’s cabin air conditioning units are equipped with integrated compact power semiconductors, and galvanically isolated DC/DC converters and inverters are used. The units can be powered directly from the 600 V or 750 V DC traction network of positive or negative polarity, depending on the place of operation. The cooling of the converters of the passenger compartment air conditioning unit is active, using the same fans as the condenser exchanger. The driver’s cabin unit contains converters with silicon carbide (SiC) semiconductors, which can be used to significantly reduce power losses, enabling the power electronics to be cooled passively; such cooling is robust, maintenance-free and economical. For the first time, we used a fully resonant topology with advanced control to stabilise the contact voltage.

Converters in the driver’s cabin contain an input circuit + DC/DC + 2xDC/AC

Key properties

- SiC-based semiconductors (DC/DC)

- IPMs (DC/AC)

- High efficiency, passive cooling outside the container (power dissipation does not heat the HVAC exhaust air, which would reduce the efficiency of cooling of the driver’s cabin)

- Low installation height

- Minimum wired connections, high reliability

Electrical parameters

- Input voltage: 400-1200V

- Output voltage: 720V, stabilised, adjustable in the range of 580V÷750V

- Input power: 5.4kW, by replacing the resonant set and changing the fitting of the units up to 14kW

- Efficiency (5.4kW version): 96-98% @5,4kWout, 400-1200Vin

- Galvanic isolation: 4kVAC

- High switching frequency: 50-150kHz

- Resonant topology adapted to a wide range of input voltages

- Zero voltage switching (ZVS) and discharge of transistors when switching off (negligible dynamic losses)

- Absence of overvoltage peaks on power semiconductors, lossless snubber

- Low EMI

- The control units in this type of air conditioning have also undergone significant innovation, reduction in size and simplification.

Characteristics

- Control via automotive Ethernet

- Internal CAN line for heating units

- Compatible with TST (Tunning and Service Tool)

- Advanced diagnostic possibilities, event and operational data log

- Integrated converters

- Continuous control of fans and compressor speed

- Contactless heating system control

- Power supply from overhead line

Technical parameters of the KLM-T2520.PLZ01 unit

- Rated cooling capacity of the unit 25 kW

- Rated heat output 20 kW

- Rated power supply voltage 750 V DC

- Operating range of supply voltage 400 V – 1000 V DC, plný výkon od 620V

- Rated control voltage 24V DC

- Refrigerant in the compressor circuit R134a

- Weight of cooling circuit components 400 kg

- Maximum air supply 3,000 m3/h.

- Operating temperature range -40 °C to + 45 °C

- Communication interface Ethernet, CAN

Technical parameters of the KLM-T0507.PLZ01 unit

- Rated cooling capacity of the unit 5 kW

- Rated heat output 7 kW

- Rated power supply voltage 750 V DC

- Operating range of supply voltage 400 V – 1000 V DC

- Rated control voltage 24V DC

- Refrigerant in the compressor circuit R134a

- Weight of cooling circuit components 150 kg

- Maximum air supply 650 m3/h.

- Operating temperature range -40 °C to + 45 °C

- Converter cooling Passive

- Communication interface CAN, Ethernet